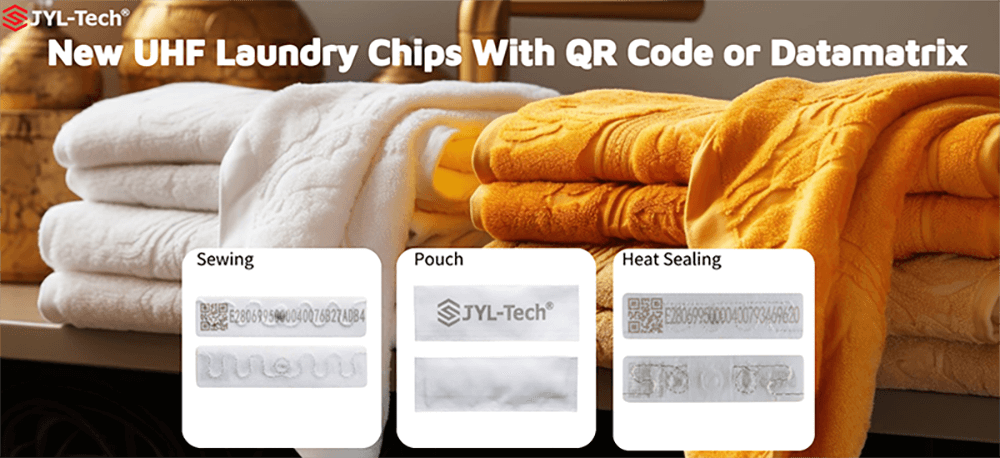

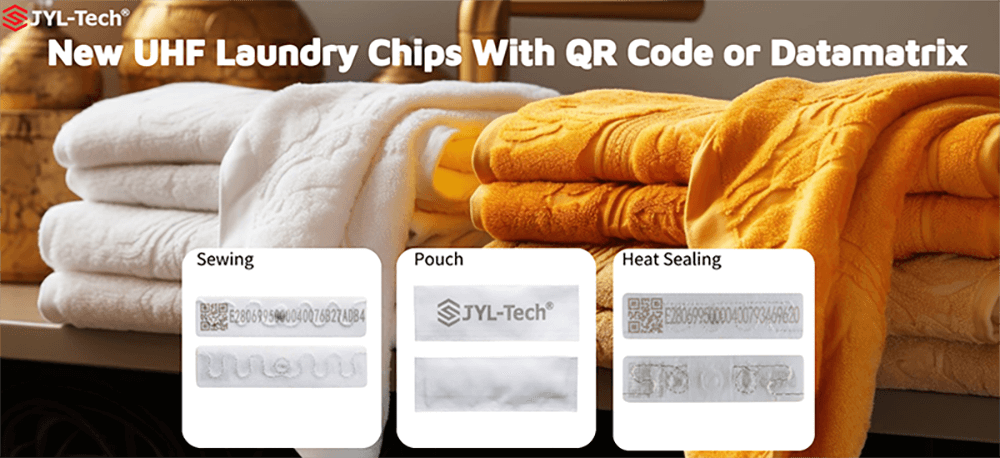

The evolution of laundry management has seen significant technological advancements in recent years, with the introduction of UHF Laundry chips leading the charge. These chips, now often integrated with QR codes or Datamatrix, are revolutionizing the way laundry services, hotels, and healthcare facilities track and manage their textiles. The combination of UHF RFID technology with visual codes like QR or Datamatrix allows for more efficient, accurate, and automated processes, reducing manual labor and human error. In this paper, we will explore the technical aspects of these new UHF Laundry chips, their applications, and the potential benefits they bring to various industries.

Additionally, we will analyze how the integration of QR codes or Datamatrix enhances the functionality of UHF Laundry chips. This dual approach not only improves inventory tracking but also opens up new possibilities for data management and customer engagement. The UHF Laundry chips are becoming indispensable in large-scale laundry operations, and understanding their capabilities is crucial for businesses aiming to stay competitive in a rapidly evolving market.

The Evolution of UHF Laundry Chips

UHF (Ultra High Frequency) RFID technology has been a game-changer in the laundry industry. Traditionally, laundry management relied heavily on manual processes, which were prone to errors and inefficiencies. The introduction of UHF Laundry chips has automated many of these processes, allowing for real-time tracking of textiles as they move through various stages of washing, drying, and folding. These chips are small, durable, and can withstand the harsh conditions of industrial laundry environments, including high temperatures and exposure to chemicals.

The addition of QR codes or Datamatrix to UHF Laundry chips further enhances their functionality. QR codes are widely recognized and can be scanned using a smartphone, providing an easy way for customers or staff to access information about a specific item. Datamatrix codes, on the other hand, are more compact and can store more data in a smaller space, making them ideal for items where space is limited. Both QR and Datamatrix codes complement UHF RFID technology by providing a visual means of identification that can be used in situations where RFID readers are not available.

Technical Specifications of UHF Laundry Chips

UHF Laundry chips operate in the frequency range of 860 to 960 MHz, allowing them to be read from a distance of up to several meters. This makes them ideal for use in large-scale laundry operations where textiles need to be tracked in bulk. The chips are typically embedded in a durable material, such as silicone or plastic, to protect them from the harsh conditions of industrial laundry processes. They are also designed to withstand multiple wash cycles, with some chips capable of surviving up to 250 washes.

The addition of QR codes or Datamatrix to these chips provides an additional layer of functionality. While UHF RFID technology allows for automated tracking, QR and Datamatrix codes provide a visual means of identification that can be used in situations where RFID readers are not available. This dual functionality makes UHF Laundry chips a versatile solution for a wide range of applications, from commercial laundries to healthcare facilities.

Applications of UHF Laundry Chips with QR Codes or Datamatrix

Commercial Laundry Services

In commercial laundry services, UHF Laundry chips with QR codes or Datamatrix are used to track textiles throughout the entire cleaning process. From the moment a garment or linen is dropped off, the chip allows for real-time tracking as it moves through washing, drying, and folding. The QR or Datamatrix code can be scanned at any point to provide additional information, such as the number of wash cycles the item has undergone or specific care instructions. This ensures that textiles are properly cared for and reduces the risk of items being lost or damaged.

Healthcare Facilities

Healthcare facilities, such as hospitals and nursing homes, often deal with large volumes of linens and garments that need to be cleaned and sanitized regularly. UHF Laundry chips with QR codes or Datamatrix provide a reliable way to track these items and ensure that they are properly cleaned and returned to the correct location. The ability to scan a QR or Datamatrix code also allows staff to quickly access information about the item, such as its cleaning history or any special care instructions. This helps to ensure that healthcare facilities maintain high standards of cleanliness and hygiene.

Hospitality Industry

In the hospitality industry, UHF Laundry chips with QR codes or Datamatrix are used to track linens and towels in hotels and resorts. These chips allow housekeeping staff to quickly and easily track the location of each item, ensuring that linens are properly cleaned and returned to the correct room. The QR or Datamatrix code can also be used to provide guests with information about the linen, such as its cleaning history or any special care instructions. This not only improves the efficiency of housekeeping operations but also enhances the guest experience by providing transparency about the cleanliness of the linens.

Benefits of UHF Laundry Chips with QR Codes or Datamatrix

The combination of UHF Laundry chips with QR codes or Datamatrix offers several key benefits for businesses in the laundry, healthcare, and hospitality industries. These include:

Improved Efficiency: UHF Laundry chips automate the tracking process, reducing the need for manual labor and minimizing the risk of human error.

Enhanced Data Management: The addition of QR codes or Datamatrix allows for more detailed data to be stored and accessed, improving inventory management and reporting.

Increased Transparency: QR and Datamatrix codes provide a visual means of identification, allowing customers and staff to easily access information about an item’s cleaning history or care instructions.

Cost Savings: By reducing the risk of lost or damaged items, UHF Laundry chips can help businesses save money on replacement costs.

Scalability: UHF Laundry chips are ideal for large-scale operations, as they can be read from a distance and can track large volumes of textiles simultaneously.

Challenges and Considerations

While UHF Laundry chips with QR codes or Datamatrix offer many benefits, there are also some challenges and considerations to keep in mind. One of the main challenges is the cost of implementing this technology, particularly for smaller businesses. The initial investment in RFID readers, chips, and software can be significant, although the long-term cost savings may outweigh these initial expenses.

Another consideration is the durability of the chips. While most UHF Laundry chips are designed to withstand multiple wash cycles, they can still be damaged by extreme conditions, such as high temperatures or exposure to harsh chemicals. Businesses need to ensure that they are using chips that are suitable for their specific laundry processes.

Conclusion

The integration of UHF Laundry chips with QR codes or Datamatrix represents a significant advancement in laundry management technology. These chips offer a range of benefits, including improved efficiency, enhanced data management, and increased transparency. They are particularly well-suited for large-scale operations in industries such as healthcare, hospitality, and commercial laundry services. However, businesses need to carefully consider the costs and challenges associated with implementing this technology to ensure that they are getting the most value from their investment.

As the technology continues to evolve, we can expect to see even more innovative applications for UHF Laundry chips with QR codes or Datamatrix. Whether it's improving inventory management, enhancing customer engagement, or reducing operational costs, these chips are poised to play a key role in the future of laundry management. For businesses looking to stay ahead of the curve, investing in UHF Laundry chips is a smart move.