MAIN FEATURES:

Item: | JYL-FL3515/3611/5512/5815/7010/7015/7018/7510/7512/7515 |

Chip: | NXP Ucode9 ( EPC 96bits, User 0 bits ), Others chips on demand |

Read Range: | From 5m ~ 7m |

Data Storage: | 50 years |

Life time: | 250 wash cycles or 3 years |

Laundry Cycle Performance:

| Washing: 90℃(194οF), 15 minutes, 200 cycle Pre-drying in Tumbler: 180℃(320οF), 30minutes Ironer: 180℃(356 ο F), 10 seconds, 200 cycles Sterilization Process: 135℃(275οF), 20 minutes |

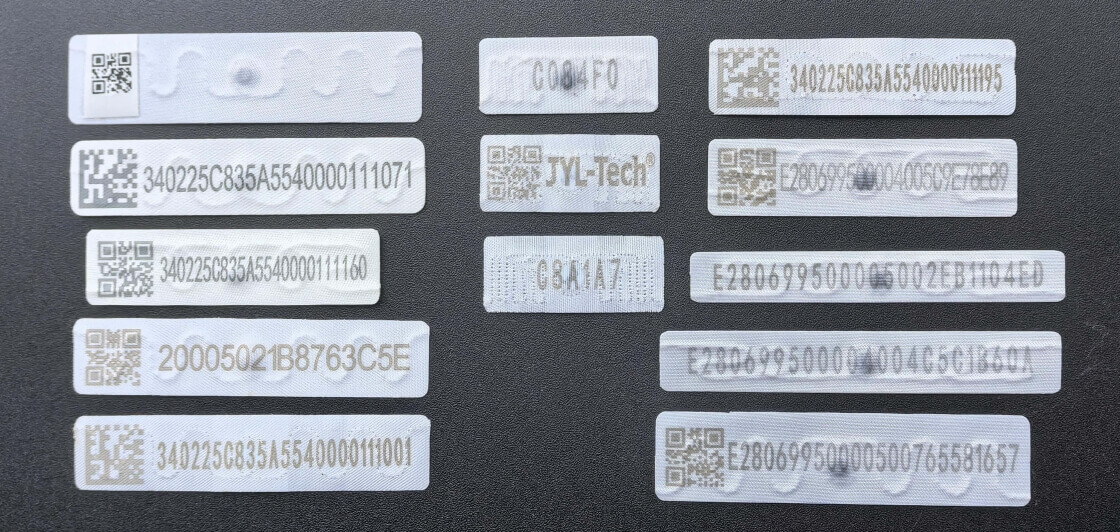

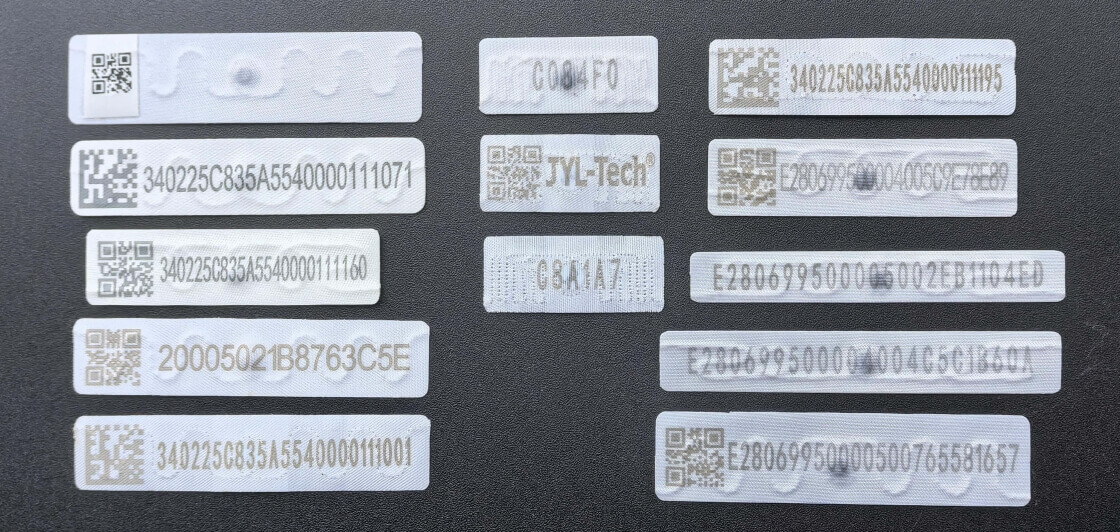

RFID Linen Tag Variable Data

- Laser-Marked: LOGO | EPC Code | Barcode | QR Code | DATA-Matrix etc

- Re-programmable: EPC Programming & Locked / Access Password

Installation method:

- Stitch Tagging (sewn) : To be stitched into the hem of a textile. Stitch the laundry tag away from the folding lines.

- Patchable (heat-sealable) : To be heat-sealed directly on the textile at +204°C (399°F), for 12~15s.

- In Pouch: To be stitched like a standard care label. Stitch the laundry tag away from the folding lines.

- Hanging: To be hung with brand tag

JYL-Tech Laundry Tag Installation Instructions.pdf

JYL-Tech Laundry Tag Installation Instructions.pdf

JYL-Tech Laundry Tag Heat Sealing Instructions.pdf

JYL-Tech Laundry Tag Heat Sealing Instructions.pdf

Laundry Tag Pouch Selections

Customizable woven materials, featuring bespoke embroidered logos on pouches. Options include tailored RFID laundry tag integration within pouches, designed to meet specific size, material, and sealing requirements, as well as the option for separate pouch packaging.

Certifications:

Applications of Washable Laundry Tag

Hotel linen management

Hospital linen tracking

Restaurant tablecloth and napkin control

Gym towel management

Spa and wellness center robes and linens

Uniforms and workwear tracking

Industrial laundry services

Linen Producer

JYL-Tech Fabric RFID Laundry Tag Datasheet - JYL-FL3515 , JYL-FL3611.pdf

JYL-Tech Fabric RFID Laundry Tag Datasheet - JYL-FL3515 , JYL-FL3611.pdf

JYL-Tech Fabric RFID Laundry Tag Datasheet - JYL-FL5512 , JYL-FL5815.pdf

JYL-Tech Fabric RFID Laundry Tag Datasheet - JYL-FL5512 , JYL-FL5815.pdf

JYL-Tech Fabric RFID Laundry Tag Datasheet JYL-FL7010 , JYL-FL7015.pdf

JYL-Tech Fabric RFID Laundry Tag Datasheet JYL-FL7010 , JYL-FL7015.pdf

JYL-Tech Fabric RFID Laundry Tag Datasheet JYL-FL7512 , JYL-FL7515.pdf

JYL-Tech Fabric RFID Laundry Tag Datasheet JYL-FL7512 , JYL-FL7515.pdf